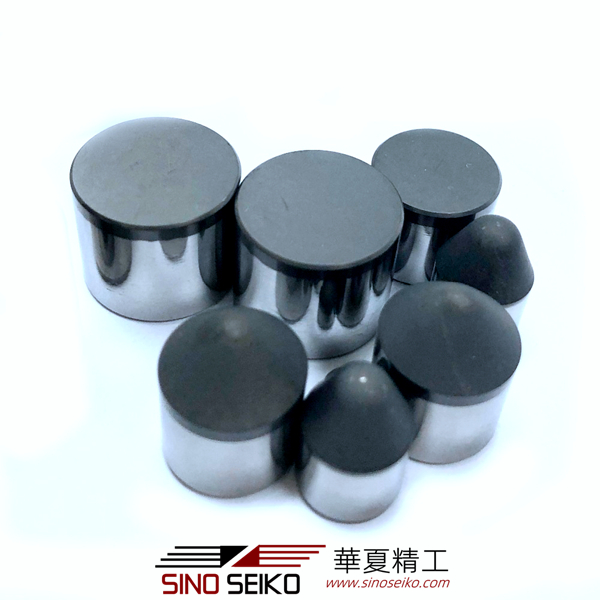

About PDC (Polycrystalline Diamond Compact) Cutter

PDC (Polycrystalline Diamond Compact) Cutter is kind of superhard material that compact polycrystalline diamond with tungsten carbide substrate at ultra-high temperature and pressure.

How PDC Cutters are made

PDC Cutters are made from tungsten carbide substrate and synthetic diamond grit. It is made using a combination of high temperature and high pressure with catalyst of cobalt alloy to help bond diamond and carbide during the sintering process. During the cooling process, the tungsten carbide shrinks at a rate of 2.5 times faster than the diamond, which combines Diamond and Tungsten Carbide together and thereafter forms a PDC Cutter.

More and more innovation happened to PDC Cutters for oil and gas drilling due to expanding market request. In 1982, PDC drill bits done only 2% of total footage drilled, but in 2010, 65% of total footage drilled was done by PDC drill bits.

Diafront is a pioneers manufacturer of PDC Cutters in China, we are dedicated to developing and manufacturing of premium quality products for oil drilling and coal mining, sincerely hope to assist you with value-added quality product and services.

Contact: Sino Seiko

Phone: +8613353772661

Tel: +8613353772661

Email: [email protected]

Add: Zhengzhou, Henan, China